EDCO VACUUM PUMPS

Should you require further information or cannot locate a product/service please do not hesitate to make contact - sales@macvalves.co.nz. Scroll through the listed products below for individual product information or click the series link you would like to view:

ER Pumps V Pumps

EV Pumps Vacuum Grippers

J Pumps Dual Venturi Vacuum Grippers

Rail Systems Variable Displacement Pumps

SM Pumps

VACUUM PUMPS

Part Number: ER2010, Vacuum Bar, T18F, T12F, SM Micro Pump, Inline Pump, DER18-PS, DER18-PSB, DER18-S24D, DER18-SB24D

The main components of ER series vacuum pumps are compact, screw-in, single-stage venturis (nozzle sets) that are available in six different capacities. The nozzles are easy to remove for cleaning. Fourteen body configurations allow choosing the style that best fits an application but performance is solely based on which venturi is selected. Low air consumption makes exhaust noise minimal. As such, silencers are not necessary.

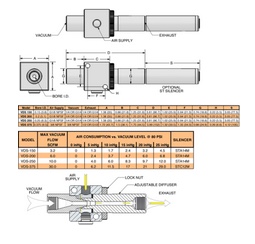

Part Number: EV05HS, EV10HS, EV15HS, EV20HS

EV Single stage vacuum generators provide a compact, lightweight, low-cost vacuum source for pick-and-place and material handling applications. The simple two-piece design allows ingested debris to exit the exhaust port. The optional ST, straight-through, exhaust silencer is a no-clog design that will pass ingested debris to atmosphere.

Part Number: Basic, PS, PSB, S24D, SB24D

J Series vacuum pumps provide performance interchanges for European brand GV pumps. EDCO J series pumps use robust aluminum bodies instead of plastic. Single-stage venturis in five different capacities from 1.2 mm to 3.0 mm allow using J series vacuum pumps in larger systems with a greater number of vacuum cups. Because of higher air consumption, exhaust silencers are always necessary.

The 1-1/2" X 3" aluminum extrusion profiles include 3/8" NPSF ports ateach end. One port is for air supply and the other for a plug or a pressure gauge. Rails are drilled to mount modules on center-to-center distances to your specifications. The minimum recommended spacing is 1-1/2" (38.1 mm) but is also dependent on vacuum cup diameter. Pilot port fittings, zone tubing and 3-way air solenoid pilot valves must be installed by the system integrator because of the many possible configurations.Single side and double side assembly options available. Vacuum sensor option available.

Part Number: SM24-38

Compact Size, Light Weight: 0.35 lbs.

Economical, Maintenance Free, Energy Efficient, Quiet Operation, High Flowrate, Brass Nozzle, Anodized Aluminum Body, Through Holes for Mounting, 100 psi Max Air Supply, Stainless Fasteners, All Metal Construction, Multi-characteristic pump with three operating pressures, Mini System also available.

Part Number: Basic - V10-60, V10-90, V10-100, V10-150, V20-60, V20-90, V20-100, V20-150, V80-200, V80-250, V90-300, V90-350, Automatic Blow-off - V10X, V20X, V80X

V Series vacuum pumps are available in 24 models with anodized aluminum bodies plus 12 cartridge models for integration into custom vacuum manifold systems. EDCO USA single-stage pumps provide the instantaneous response common to air operated devices in addition to being compact,light, and cost-effective. Rugged, all-metal construction provides years of trouble-free service.

Part Number: VG18, VG38, VGP38VG Models

Options available include: Purge option, Sensor Port option, M4 Plate Mount feature, Swivel Mount feature, T-Nut Kits and Cup Fitting adaptors.VGP Models - Options available include a variety of mount options and PP or LP purge options.

Exhaust adaptor, PP or LP Purge options, and either standard M4 plate or swivel mount options available.

VDS vacuum pumps can provide over 20" Hg (68 kPa) and their straight through, non-clog design is ideal for very dusty and dirty applications such as bag filling or handling ceramics or masonry products. The square body and two mounting holes makes the VDS pump easy to attach to any flat surface. A straight through silencer will not accumulate debris and will pass it out with the exhaust air.